NORD DRIVESYSTEMS at SPS 2025

| Company | NORD DRIVESYSTEMS |

|---|---|

| Date | 01.10.2025 |

SPS visitors can see the effectiveness of NORD’s NXD tupH® surface protection for themselves during a live demonstration. Image: NORD DRIVESYSTEMS

Smart drive solutions for automated production

Move smarter: At SPS 2025, NORD DRIVESYSTEMS will present itself as the solution provider for intelligent drive concepts in smart production. Visitors can experience live how drive systems from NORD can solve any motion task. The focus is on multivariable drive electronics, effective NXD tupH® surface protection and digital NORD services ranging from virtual commissioning to predictive maintenance.

At SPS – Smart Production Series from 25 to 27 November 2025, NORD will demonstrate how the system provider implements smart drive solutions for automated production. One key element is intelligent control via decentralised and centralised drive electronics that are in focus at NORD’s stand 431 in Hall 3A at the trade fair centre in Nuremberg.

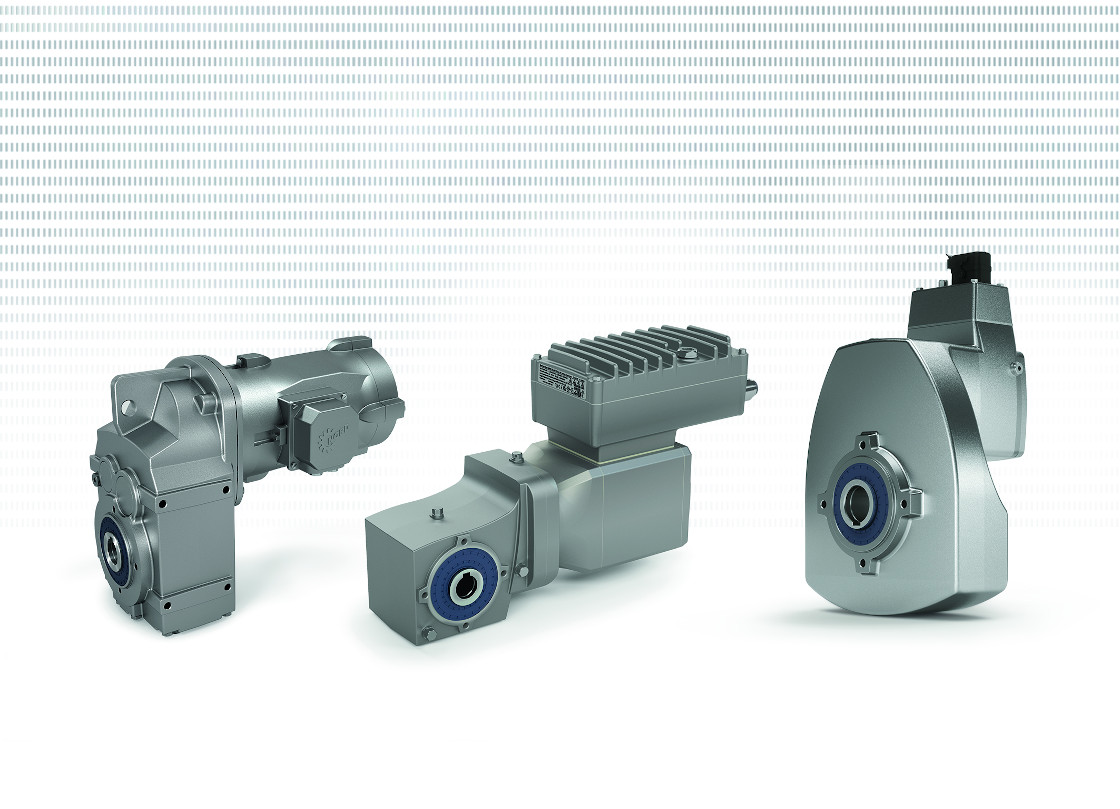

Drive electronics for any system architecture

“With the product families NORDAC PRO, NORDAC ON, NORDAC FLEX and NORDAC LINK, NORD has a portfolio that benefits drive systems in automated production”, says Jörg Niermann, Head of Marketing at NORD DRIVESYSTEMS. This enables the inverters to be flexibly used in any system architecture: They allow installation both in a control cabinet and in the field – directly mounted on the motor or close to the motor. In addition, they support all common Ethernet protocols, in some cases via multi-protocol Ethernet interfaces.

Another advantage of the NORDAC frequency inverters are their numerous added-value functions: Thanks to embedded features such as the POSICON positioning mode or the on-board PLC, drive solutions are also able to perform tasks that are normally carried out by the higher-level control unit. At SPS, NORD will also present drive-based functional safety of its drive electronics, which includes local fail-safe sensors and actuators such as emergency stops or safety lights grid.

Live demonstration: NXD tupH® surface speeds up cleaning process

Visitors can see the effectiveness of the NXD tupH® surface protection for themselves during a live demonstration. NXD tupH® is the surface protection for extreme conditions in wash-down areas. It makes aluminium housings resistant to acids and alkalis. A treatment that creates a very hard, inert surface forms the basis. For NXD tupH®, the treated housing parts are coated with a strongly adhesive high-performance sealer and then hardened. The structure and adhesion of the sealer prevents flaking – minor damages cannot spread. This makes NXD tupH® the ideal surface protection for hygienically sensitive applications such as food processing or pharmaceutical manufacturing. “At the trade fair stand, we will use wash-down models to demonstrate how components with NXD tupH® or smooth surfaces also facilitate and speed up cleaning, thereby saving valuable process times”, says Niermann.

Data-based for optimal results: Digital services increase efficiency and availability

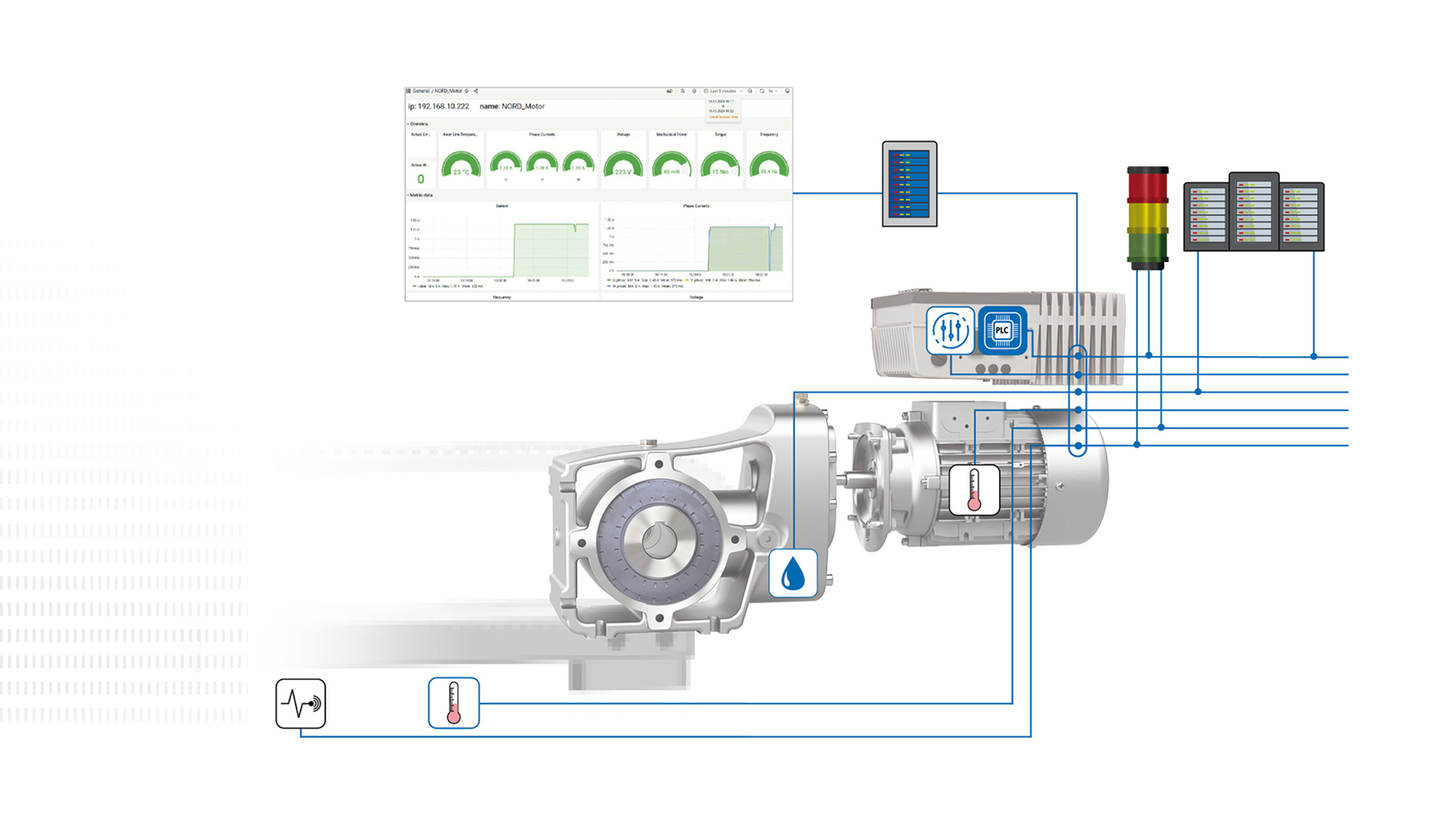

Another NORD topic at SPS: The data-based services used by the solution provider to enable optimum performance of its drive systems in every life cycle phase. For the operational phase, NORD offers its NORD ECO service. The NORD ECO box records permanent loads, load peaks and irregular conditions. The evaluation of the data reveals savings potential and forms the basis for drive optimisation. “We often encounter drive systems that are oversized”, reports Niermann. “Our NORD ECO service almost always results in lower total cost of ownership.”

With its IIoT solution NORD DRIVE MONITOR, the drive expert also supports users in the maintenance phase with condition monitoring for predictive maintenance. NORD DRIVE MONITOR continuously provides dynamically calculated and sensor-recorded operating values from electronic drive systems for further processing. Users can thus identify any anomalies or wear at an early stage, and plan maintenance measures. “Downtimes are therefore reduced effectively, and the service life of machines and systems as well as the overall system efficiency are increased”, explains Niermann.

As a new service for the planning phase, NORD is presenting simulation models for the virtual commissioning of its components for the first time at SPS. The digital twins can be comprehensively tested in a simulated system, allowing errors to be corrected at an early stage of development. Once the drive system has been validated by the customer, it is manufactured by NORD. The fact that the drives are then already functionally integrated into the system control accelerates the actual commissioning process. The entire process, from configuration to commissioning, is thus reduced from several months to just a few weeks.

With the IIoT solution NORD DRIVE MONITOR, NORD provides operating values of electronic drive systems for further processing. Image: NORD DRIVESYSTEMS

Contact

Member of the NORD DRIVESYSTEMS Group

Getriebebau-Nord-Straße 1

D-22941 Bargteheide/Hamburg

Germany

- +49 4532 289 - 0